Everlasting Valve Company invented one good idea and stuck with it. They created the rotating disc valve over 100 years ago, and have only made it better since. Calling it the “everlasting valve” isn’t far from the mark—these valves actually develop a tighter seal over time, rather than weakening. They’re also available in special configurations for a wide variety of purposes, and can be customized to meet any need.

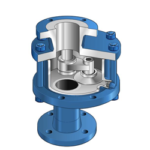

How It Works

The rotating disc valve moves a disc into place to block product, and moves it out of the way to open the line again when needed. What’s unique about this valve is that the disc rotates as it moves into place, so that it is effectively “self-polishing.” This has been proven to wear away scratches and imperfections and form a tighter seal with use.

The rotating disc valve moves a disc into place to block product, and moves it out of the way to open the line again when needed. What’s unique about this valve is that the disc rotates as it moves into place, so that it is effectively “self-polishing.” This has been proven to wear away scratches and imperfections and form a tighter seal with use.

Check out the specific process valves below, or contact us to see how we can customize them for you.

High Pressure Abrasion Resistant Valves

Used for materials of all kinds, across many industries. There are very few valves that can stand up to abrasion as well as a self-lapping Everlasting Valve.

Used for materials of all kinds, across many industries. There are very few valves that can stand up to abrasion as well as a self-lapping Everlasting Valve.

Abrasion Resistant Diverter Valves

Used to maximize process efficiency, load multiple vessels or silos, and for a variety of diverter applications. These valves allow rapid switching even with abrasive products, slurries and dry powders.

Used to maximize process efficiency, load multiple vessels or silos, and for a variety of diverter applications. These valves allow rapid switching even with abrasive products, slurries and dry powders.

Reactor Loading Valves

Used in chemical plant reactors, petrochemical operations and reactors around the world, this is a trusted and durable way to control your reactor loading process.

Used in chemical plant reactors, petrochemical operations and reactors around the world, this is a trusted and durable way to control your reactor loading process.

Abrasion Resistance Slurry Valves

Abrasive slurries are one of the hardest types of substances to work with, and take a hefty toll on equipment. The self-lapping nature of the Everlasting Valve makes it a star performer with slurries, no matter what the application.

Abrasive slurries are one of the hardest types of substances to work with, and take a hefty toll on equipment. The self-lapping nature of the Everlasting Valve makes it a star performer with slurries, no matter what the application.

Severe Duty Shutoff Valves

The metal-to-metal design of an Everlasting Valve means it stands up to repeated shutoff in severe duty applications, staying tight or getting tighter with time.

The metal-to-metal design of an Everlasting Valve means it stands up to repeated shutoff in severe duty applications, staying tight or getting tighter with time.