InterSystems is owned by GSI and has a long history manufacturing exceptionally high-quality product samplers. Their industrial product sampling systems and rugged, reliable and specialized for a variety of different materials and processes.

In many industries, the traditional method of getting a product sample was to do it by hand. This works, but it has drawbacks: sample size varies, certain size grains or granules are more likely to be gathered than others, and the sample is anything but random. That’s why we prefer to rely on InterSystems.

Gravity Chute Samplers

Gravity chute samplers are installed in gravity flow pipes or in the spouts of hoppers. They are ideal for sampling free-flowing materials, including pellets, granules, chips, flakes and powders. InterSystems has a variety of models to fit different set up and handle different types of materials.

Gravity chute samplers are installed in gravity flow pipes or in the spouts of hoppers. They are ideal for sampling free-flowing materials, including pellets, granules, chips, flakes and powders. InterSystems has a variety of models to fit different set up and handle different types of materials.

When activated, the samplers sweep through the product and gather a true cross-cut sample, providing accurate information about your product.

Sloped Gravity Chute Samplers

These work the same way as other gravity chute samplers but are optimizes for sloped chutes, often taking up very little space.

These work the same way as other gravity chute samplers but are optimizes for sloped chutes, often taking up very little space.

Pneumatic Line Samplers

Every InterSystems pneumatic line sampler is designed to eliminate stream obstruction and keep your line sealed. Samplers enter the line only when activated, then fully retract and seal off the line behind them. Models are available for vertical and horizontal lines, and can work with materials including liquids, solid suspensions, large granules and powders—even microscopic powders.

Every InterSystems pneumatic line sampler is designed to eliminate stream obstruction and keep your line sealed. Samplers enter the line only when activated, then fully retract and seal off the line behind them. Models are available for vertical and horizontal lines, and can work with materials including liquids, solid suspensions, large granules and powders—even microscopic powders.

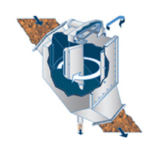

Belt Samplers

Unlike many belt samplers, InterSystems’ products are able to provide repeatable, representative samples even in the open environment of a belt. Different models can be placed mid-belt or at belt and can handle virtually any material, including abrasive materials.

Unlike many belt samplers, InterSystems’ products are able to provide repeatable, representative samples even in the open environment of a belt. Different models can be placed mid-belt or at belt and can handle virtually any material, including abrasive materials.

Bin, Hopper, and Pit Samplers

Specialized collectors can be used for sampling from bins, hoppers or pits with precision and accuracy.

Specialized collectors can be used for sampling from bins, hoppers or pits with precision and accuracy.